INNOVATIVE STONE-CUTTING TECHNOLOGIES

Once the block of stone has been extracted from the ground, it is cut – in other words slabbed – into the required shapes.

Stonemasonry technologies have been continually evolving, but the new technologies introduced today are rarely revolutionary. The latest revolution in the field of block slabbing was the introduction of wire saws.

Light wire saws are relatively easy to install and they have quickly replaced large, heavy and often faulty pendulum saws. At first many doubted the service life of the wires as well as the accuracy and running costs of wire saws, but they soon became so popular that today the demand for pendulum saws is very limited.

Before the wire saws were introduced, designers were trying to develop a stone-cutting machine that would work on the same principle as the pendulum saw, but which would use diamond blades. Several prototypes of such saws were produced, but they could not compete with the traditional saws equipped with steel beads or wires. Furthermore, designers are developing technologies that will allow for a thinner cut and increase the effectiveness of wire saws.

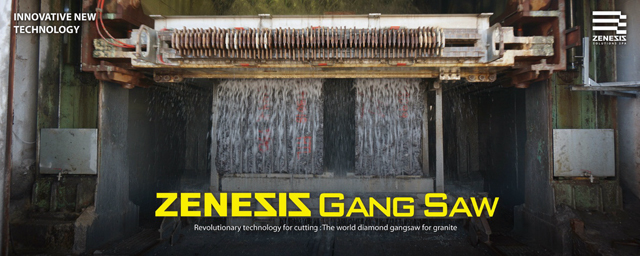

It has become customary that anything new in the area of stone cutting machinery comes from Italy. However, this time the new machine was patented in Korea. The new technology was implemented by a Korean company EHWA Diamond Industrial Co. The patent involves a revolutionary system of cutting granite blocks with patterned steel blades equipped with special diamond segments. The system is called Zenesis Gang Saw (ZGS) and is produced by an Italian-Korean company Zenesis Solution Srl.

The ZGS system uses patterned steel blades with special diamond segments attached to a standard pendulum saw. The greatest advantage of the new system is that it can be installed in existing granite pendulum saws.

The ZGS system uses less energy as well as material; the 5 mm cut allows for a lot less waste.

A two-metre block can be cut into 8 to 10 slabs, each 5 mm thick.

The system allows for a much faster cutting than an average saw (100-150 mm/h) and is extremely precise.

ZGS can be used to cut virtually any stone, be it granite, marble, limestone, quartzite, etc.

All calculations and installations must be executed by authorised Zenesis Solutions Srl consultants. Attaching the ZGS system to an existing machine requires both new components (new tensioner and high-strength bars) and modifications to the saw frame. Diamond segments require higher cutting tension than traditional saws.

Source: Kurier kamieniarski

Author: Kurier Kamieniarski | Published: 05.11.2018