SZYDŁOWIEC SANDSTONE

The sandstones of Szydłowiec have been known for a very long time. The whole of Szydłowiec is located on sandstone deposits and as early as the 15th century buildings were built using this stone. It was mined and is still mined from various quarries. Stones from different deposits may differ slightly in colour or shade, but their parameters and physical-mechanical properties are almost identical.

The history of the use of Szydłowiec sandstone is perfectly visible in the architecture of cities such as Warsaw, where many buildings were built using this stone, and in the post-war period many of them were rebuilt, renovated, restored and revitalised using this sandstone.

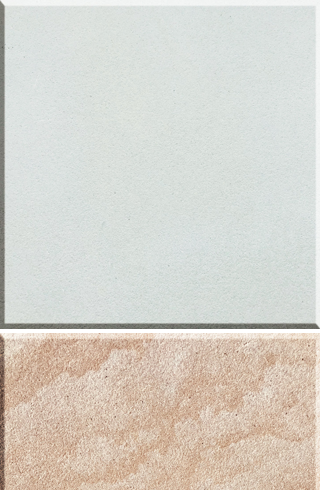

This history includes the “Szydłówek – Saspol” mine, where mining began in 2016. The stone from this quarry is a typical example of Szydłowiec sandstone. Depending on the depth of extraction, white and beige coloured sandstone can be obtained. Both have the same physical and mechanical parameters. They are characterised by fine, even very fine grains with a silica binder.

It is worth noting that it is possible to select it in such a way that it is 100% pure white. On the other hand, it is difficult to select a perfectly beige material – a beige colour should rather be treated as a discolouration, streaks or veins.

In a large format it will be difficult to achieve a uniform beige colour. However, the white varietion can be used to create large surfaces with a uniform colour. The purity of colour is unique in the world – it is difficult to find another sandstone of such uniform and bright colour.

Szydłowiec sandstone is well suitable for outdoor use. Laboratory tests confirm its resistance to weather conditions, including low water absorption and total frost resistance. With time, it covers itself with patina and hardens even more.

Impregnation is not necessary, but it is recommended. Like all sandstones, when exposed to external conditions it can turn grey and patinate. Impregnation allows you to enjoy its natural colour and appearance for longer, just like right after installation.

Those who work with various sandstones emphasise that it is incredibly easy to work with this material. Thanks to its fine grain and compactness it perfectly shows details and allows for precise drawing of details.

Szydłowiec sandstone very well susceptible to mechanical processing. However, taking into account the wear of tools it is demanding and you need to choose the right tools for it. Certainly, all tools will cut it, but some will have a low service life – it is characterised by high abrasiveness, i.e. high abrasive wear of tools. This makes it suitable for sharpening diamond tools.

It is available in various surface finishes. It is supplied as standard with a ground, pebbled, split and pointed surface. At the request of architects, fluted, notched and mirrored surfaces were also produced.

It can be used virtually anywhere. Due to its texture, it is not recommended for horizontal interior cladding, where it may cause problems with keeping it clean, and despite impregnating the surface it may not resist wine or coffee stains.

However, it looks great on decorative walls – with a polished or split texture. One of the most interesting realisations of its kind is the production of a wardrobe – including fronts – ordered by one of the architects.

Source: Kurier kamieniarski

Author: Paweł Szambelan | Published: 10.05.2021