INNOVATIVE SOLUTION FOR PRODUCING LETTERS

When making gravestones designing inscriptions is a very time-consuming process. It is also a process that can easily damage a gravestone. These issues are well-known to all gravestone producers and suppliers of inscriptions.

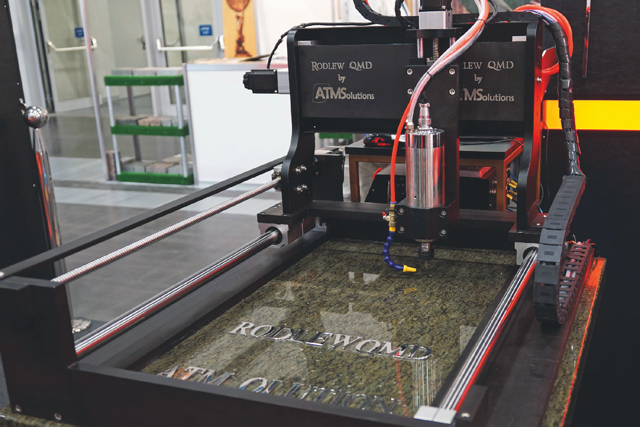

Therefore, the new machine Stone Drill 4070 has been invented. The machine makes precise drilling of holes for fastening inscriptions possible. The idea emerged in Rodlew company QMD – a well-known inscription supplier. ATMSolutions, a producer of numerically controlled machines, Waterjeta was invited to cooperate on machine development.

It was software development that was a crucial matter. A genuine computer programme created by experts from ATMSolution facilitates designing inscriptions for a particular gravestone. A complete inscription is put on a working surface. Then, letter fonts and distance among letters, words, and words within the inscription are set. The programme counts the coordinate position of each hole for the given letter and starts the drilling. The machine works with the same set of coordinates for fastening pins which ensures that the placement of holes is precise and flexible for inserting each individual letter.

Years of experience of Rodlew QMD company has implemented many innovative and practical solutions in the field of stone drills. First, the machine is fully automated: stepping operation, it can stop itself in case of issues such as drill break. It can restore operation in the last place after removing the issue. The machine enables automatic positioning after a drill change. Drilling is done without impact – a drill in and out so it is unlikely that the stone will be damaged by drilling. Quiet operation, low weight, and easy stone drilling are important assets of the machine. The machine is certified by CE.

A prototype introduced at the STONE fair aroused participants’ interest, and it confirmed that such structural design is very much in demand on the market. A meeting with customers in Poznan inspired the company to come with a new idea. The next machines could be equipped with engraving heads for incising a design onto a stone.

At present, the engraving head passes stress tests, and the test machines will be available next spring. The manufacturer plans to invite companies that decide to buy the first series machine for testing. These cooperating companies will then collect feedback and structural design for machine improvement. Those companies which decide to cooperate on machine trials will be given special maintenance care and service by our company.

Source: Kurier kamieniarski

Author: Kurier Kamieniarski | Published: 20.12.2016