INSTALLING COUNTERTOPS 1

In the previous article, in which we discussed various tools used in the production and installation of countertops, I expressed the opinion that salespeople believe that the hardest part of the process is to sell the countertop, stonemasons claim that the most difficult is to make it, and installers to install it.

Since then I have been told by a stonemason that for the client the trickiest part is choosing the colour…

Let us assume that the colour has been selected, the upper part of the countertop made, and now it is on its way to the client. Then the van transporting the countertop safely arrives at its destination. Until the countertop is installed, any handling represents a risk. The countertop is long and has holes that weaken it – therefore we need to use various kinds of reinforcement to ensure safe handling. Given the size of the countertop, the most practical option are longitudinal rails.

The company Omni Cubed, Inc. produces several types of material reinforcement. They are all made of aluminium rails and include carry clamps or suction cups.

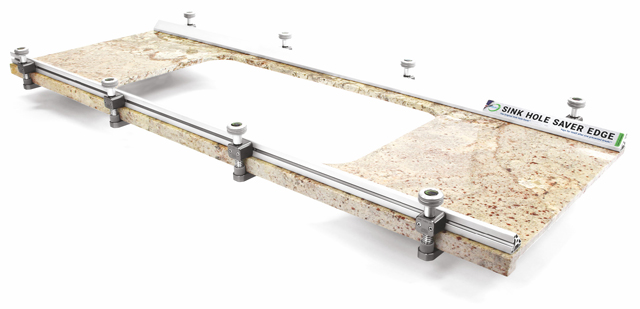

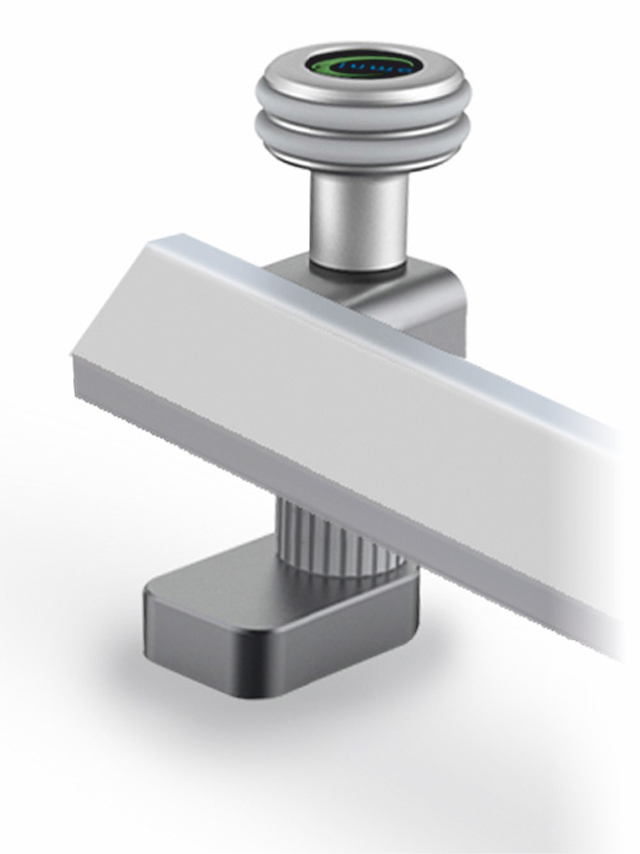

The simplest type of material reinforcement is Sink Hole Saver™ Edge equipped with mechanical clamps that have a clamping range from 17 to 51 mm, and adjustable tightening knobs. The Sink Hole Saver™ Edge is available in three lengths – 120, 180 and 240 cm.

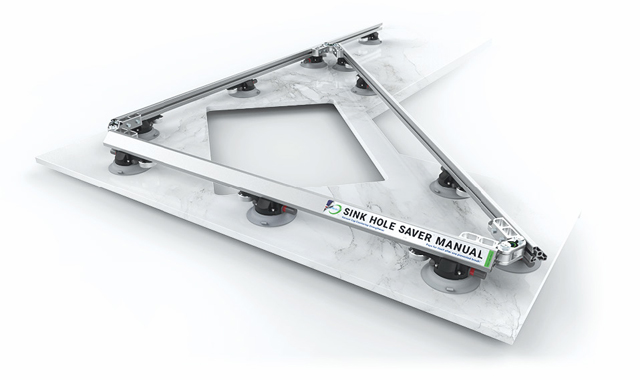

Other options are Sink Hole Saver™ Manual or Sink Hole Saver™ Auto – these are reinforcement rails equipped with concaved vacuum cups. The Auto Saver uses rechargeable vacuum pump, the Manual Saver is operated manually. The Auto Saver is particularly suitable for transportation of materials with satin surface finishes.

Rails with suction cups have an advantage over rails with clamps where there is a limited access to the edge of the countertop during installation, for example where there is no access from three directions or from above.

Another tool that promotes safe handling of countertops are carry clamps Aqua-Jaw™ Carry Vise™ – these are mechanical clamps with a clamping range from 4 to 108 mm and comfortable foam handle grips. In their reviews customers claim that using Aqua-Jaw™ Carry Vise™ is the safest way to transport stone.

Looking at the Omni Cubed range of products, you can tell at first sight how different they are from similar products on the market: they are made with great care from high-quality, stable and durable materials. Before the products are launched on the market, they undergo a number of tests in the place of production (i.e. in Northern California). Special attention is paid to the product safety.

Artur Zskoła (Prodmar):

We have bought several Omni Cubed products and I am thinking of getting some more.

We produce and install all kinds of countertops. Some have large cut-outs and are therefore rather difficult to install. We have to be very careful not to damage the stone during installation. Our installers often face all kinds of challenges at the client’s premises. Even when there is a lift available, it is often better to use the staircase, because the lift might be too small or difficult to access. This often causes a certain level of nervousness during handling and installation.

Eight months ago we decided to buy two Omni Cubed reinforcement rails. This decision proved to be a very good one. Our installers were happy with the rails, because they have made handling and installing the countertops much easier. The whole installation process has been shortened, which has a positive effect on the company’s efficiency and profitability. These new tools are so useful that we bought two more reinforcement rails.

They work so effectively that we have researched other Omni Cubed products in the same category and are thinking of buying pneumatic belts with a miniature battery-powered compressor.

Zdroj: Kurier kamieniarski

Author: Tomasz Rogala | Published: 20.12.2018