DIAMOND TOOLS FOR CONCRETE AND STONE FLOOR FINISHING

Over the last years, the demand for metal-diamond tools used for working concrete and stone surfaces has been growing. Founding many private stonemason factories has had a huge importance for the next development, an increase in the production of several types of cladding, masonry, floors, paving from materials such as granite, marble, sandstone, limestone, or concrete.

A key element in the construction of metal-diamond tool is the head which should show high ability to keep the diamond parts and, at the same time, to wear down at the same speed as they wear down.

Cobalt and its alloys are used widely as the matrix material thanks to their excellent retentive characteristics and resistance against abrasive wear. The disadvantage of cobalt is its high and unstable price. This is why in the reactions to the growing prices of commercial dust Co-20% WC (cobalt with 20% of wolfram carbide) and Fe-Cu-Co-WC (from the system iron-copper-cobalt and wolfram carbide) which are usually used when making professional metal-diamond tools for surface treatment of concrete and stone, a study was done with the goal to create a cheaper matrix that would allow the elimination of materials that were used so far.

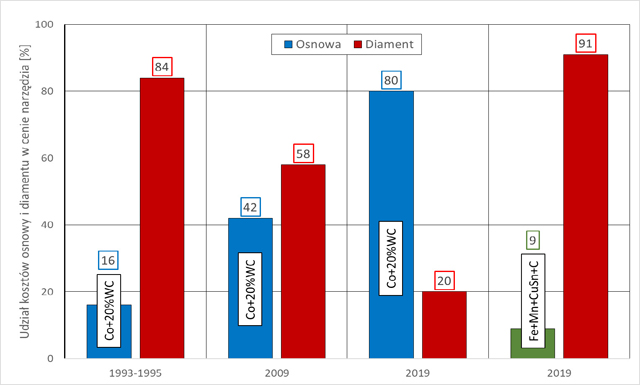

The research was done taking into consideration that the price of the matrix has become the main material factor that determines the price of the tool. Its share on the costs of raw materials needed to make one segment of metal and diamond of the sizes 40 x 10 x 10 mm goes up to 80 %. While in the 1920s, it was around 7-18 % (image 1).

Source: Kurier kamieniarski

Author: Elżbieta Cygan-Bączek | Published: 03. 03. 2021