Work procedure when constructing stone objects

This concise manual should help you to follow basic principles for understanding preparation activities, placement and tiling/facing. We recommend you to exploit craftsmen whose speciality is natural stone.

Tiling/Facing

Tiles are glued to sandy cement blend in a ratio 1:1 or usual industrial glues from building supply store can be used. It is important to buy flexible glue which serves for tiling/facing or pavement in an exterior. Most producers declare that if is a glue with the best properties from all other glues in their range of products.

Cemix 045 is widely used glue for suitable fastening. Some producers such as Hasit offers a special glue for gluing stone tiles. It is important not to buy flexible glues of medium series (such as Cemix 035 plus) which are to be used for gluing smaller ceramic paving and tiling in an exterior.

Jointing of the tiles is carried out by jointing material which is applied to the level with the stone or 5 millimetres under tiles so the surface will look three-dimensional. As a jointing material we can use sandy cement blend in a ratio 1:2 with potential coloration for required colour shade. When jointing in exterior it is necessary to buy flexible jointing materials.

Paving

Paving into sand

Placement of stones is carried out for pavements in widths from 4 – 10 centimetres.

Composition of layer order is shown in the following chart:

A) Pavements, terraces – paving 4 – 7 centimetres,

1st subsoil layer – gravel size of 8 – 16 centimetres, layer thickness 10 – 15 centimetres,

2nd subsoil layer underlying rubble size of 4 – 8 centimetres, layer thickness approx. 3 centimetres,

3rd subsoil layer underlying rubble size of 4 – 8 centimetres, natural stone paving size of 4 – 7 centimetres.

B) Areas for cars, roads, car parks – paving size of 7 – 10 centimetres,

1st subsoil layer – gravel size of 16 – 32 centimetres layer thickness 20 centimetres,

2nd subsoil layer – gravel size of 8 – 16 centimetres layer thickness 10 – 15 centimetres,

3rd subsoil layer underlying rubble layer thickness approx. 3 centimetres,

4th subsoil layer natural stone paving size of 7 – 10 centimetres.

We cover the area where we had placed natural stone with jointing material. When preparing subsoil and placing stones we recommend to secure good drainage for rainwater. Subsoil is strengthened by inserting reinforced nets into gravel.

Paving into concrete

Paving into concrete is carried out for pavements in widths from 1 – 4 centimetres.

Composition of layer order is shown in the following chart:

A) Pavements, terraces – paving 1 – 2 centimetres,

1st subsoil layer – gravel size of 8 – 16 centimetres, layer thickness 10 – 15 centimetres,

2nd subsoil layer gravel size of 4 – 8 centimetres, layer thickness approx. 3 centimetres,

3rd subsoil layer concrete blend layer thickness 5 – 10 centimetres,

4th subsoil layer natural stone paving size of 1 – 2 centimetres.

B) Areas for cars, roads, car parks – paving size of 2 – 4 centimetres,

1st subsoil layer – gravel size of 16 – 32 centimetres layer thickness 20 centimetres,

2nd subsoil layer – gravel size of 8 – 16 centimetres layer thickness 10 – 15 centimetres,

3rd subsoil layer concrete blend layer thickness layer thickness 10 – 20 centimetres,

4th subsoil layer natural stone paving size of 2 – 4 centimetres.

Paving is glued to concrete areas thanks to building glue (see tiling), or it is placed directly into concrete blend with consequent jointing. Thin paving can be glued to sandy cement blend in a ratio 1:1. Concrete blend should be strengthened by reinforced nets.

Other uses:

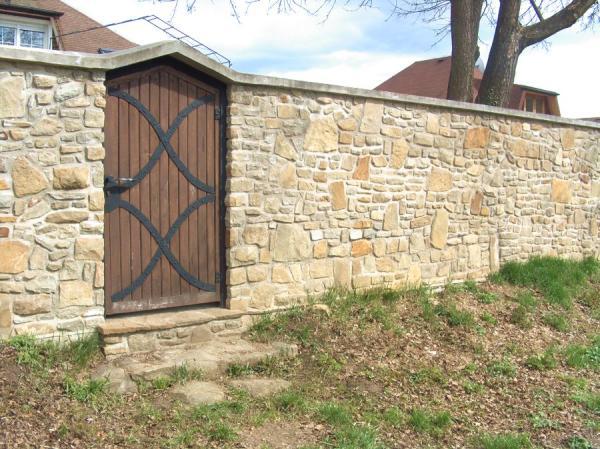

Except from tiling and paving our imported stones have other uses which is dependent on the imagination of architects, designers, builders or gardeners.

Source: www.ceskestavby.cz